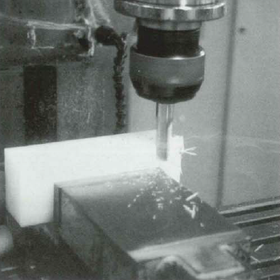

Ultra-high molecular weight polyethylene "MEP UHMW"

Materials that are physiologically non-toxic! They are used not only for food applications but also in the medical field.

"MEP UHMW" is ultra-high molecular weight polyethylene with a molecular weight ranging from 5 million to 9 million, which is extraordinarily high compared to other polymer materials. Its color and appearance are indistinguishable from general high-density polyethylene (with a molecular weight of tens of thousands to hundreds of thousands), but it far surpasses them in physical and chemical properties. Additionally, its water absorption rate is almost zero, meaning that even when used in water, there is no swelling or reduction in strength due to water absorption. [Features] ■ Highly wear-resistant ■ Slippery ■ Difficult to break ■ Non-adhesive ■ Non-toxic and safe *For more details, please download the PDF or feel free to contact us.

- Company:カテックス 工業用品営業本部

- Price:Other